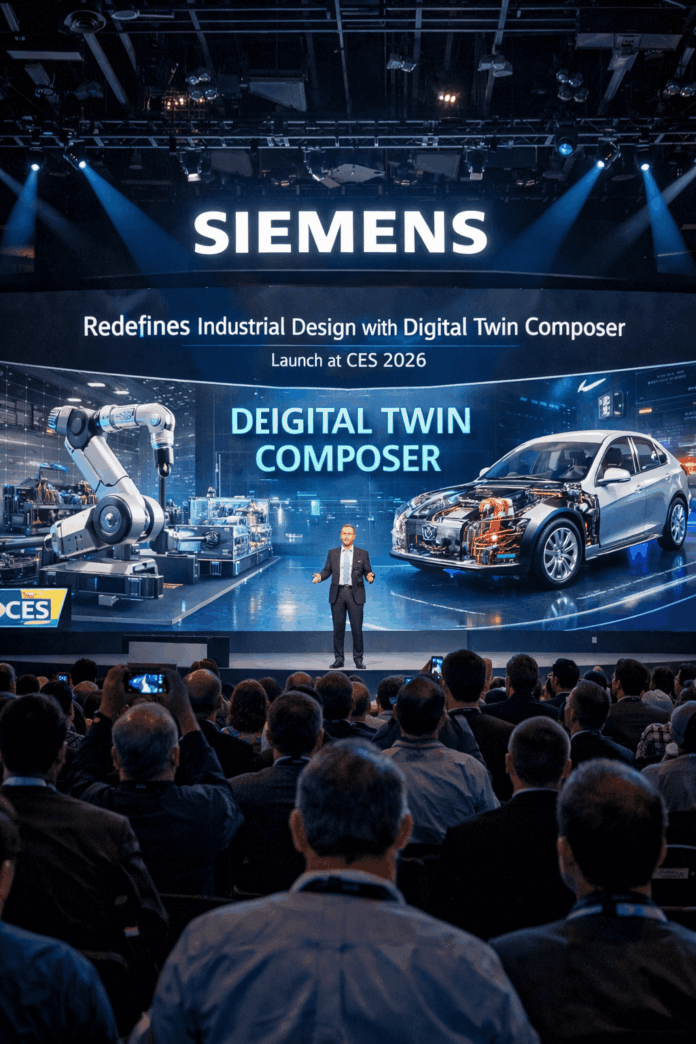

The future of manufacturing no longer requires breaking ground before breaking problems. On January 5, 2026, Siemens unveiled Digital Twin Composer at CES 2026, a transformative software platform that enables companies to design, test, and optimize entire factories in virtual environments before committing a single dollar to physical construction. Built on NVIDIA Omniverse libraries and integrated within the Siemens Xcelerator ecosystem, the platform represents a fundamental shift in how industries approach capital investment and operational efficiency.

The Industrial Metaverse Becomes Operational Reality

Digital Twin Composer merges 2D and 3D digital twin data with real-time physical information from manufacturing execution systems, quality management platforms, programmable logic controllers, and industrial IoT sensors across an open ecosystem of engineering data. The result is a continuously updated, photorealistic virtual representation of real-world systems where engineering, operations, and design teams collaborate on a single, consistent model.

Siemens President and CEO Roland Busch positioned Industrial AI as the transformative force that will reshape the next century, just as electricity once revolutionized the world. The platform enables large-scale simulation and virtual commissioning of entire facilities, autonomous robot training for lights-out manufacturing, and full operational context testing of products and production systems. Companies can now walk through new factories, test production lines, and refine designs—guided by AI that continuously learns, simulates, and optimizes every decision—before any physical component exists.

PepsiCo’s Breakthrough Results

PepsiCo’s early deployment of Digital Twin Composer at a U.S. Gatorade manufacturing plant delivered immediate, measurable impact. Within just three months, the facility achieved a 20 percent increase in throughput, demonstrating the technology’s capacity for rapid operational transformation. The collaboration, announced at CES 2026 by Siemens CEO Roland Busch and PepsiCo’s CEO Latin America and Global Chief Strategy & Transformation Officer Athina Kanioura, represents an industry-first multi-year partnership to transform PepsiCo’s global supply chain using digital twin technology and artificial intelligence.

The financial implications are equally significant: PepsiCo estimates a 10-15 percent reduction in capital expenditures by uncovering hidden capacity and validating designs virtually, allowing the company to optimize existing assets rather than investing in costly new construction. The platform identified 90 percent of potential issues before physical modifications, achieving near 100 percent design validation while compressing facility design and optimization cycles from months to days.

PepsiCo is no longer reacting to operational challenges but anticipating them, using the digital world as a proving ground for the physical one. The company now simulates, validates, and optimizes factory layouts before physically building, reducing risk and revealing hidden capacity across global manufacturing networks.

Technical Architecture and Capabilities

The platform’s foundation rests on the connection between Siemens Xcelerator and NVIDIA Omniverse, creating an industrial metaverse with physics-based digital models and real-time AI capabilities. This integration opens NVIDIA’s Omniverse and AI ecosystem to industrial automation built using Siemens’ mechanical, electrical, software, IoT, and edge solutions.

Digital Twin Composer supports high-fidelity industrial visualization while maintaining enterprise-grade security, designed to scale across complex industrial scenarios without compromising performance or accuracy. The platform integrates with Siemens’ industrial AI and data science software, including RapidMiner and other AI solutions, delivering virtual world intelligence and real-time insights for confident decision-making.

NVIDIA CEO Jensen Huang emphasized the shared vision: “Siemens and NVIDIA share a common vision that the industrial metaverse will drive digital transformation. The connection to Siemens Xcelerator will open NVIDIA’s Omniverse and AI ecosystem to a whole new world of industrial automation”.

Expanding the Industrial AI Ecosystem

Beyond Digital Twin Composer, Siemens announced nine new Industrial Copilots in partnership with Microsoft to streamline manufacturing and operations by bridging information technology and operational technology. The company also unveiled integrations with Meta Ray-Ban AI Glasses for shop floor efficiency and partnerships with Commonwealth Fusion Systems to accelerate the path to commercial clean fusion energy.

Guillaume Cordonatto, Director of Digital Enterprise Innovation at Siemens, notes that Digital Twin Composer aligns with the company’s vision of helping manufacturers address complexity, accelerate production, reduce costs, and improve profitability while enhancing resilience and sustainability. The platform will become available mid-2026 through the Siemens Xcelerator marketplace.